A very small budget might prompt you to do the concreting job on your own. A concrete floor in addition serves as an optimal base for installation of some other flooring solutions as carpets, tiles along with hardwood. Concrete flooring is in addition a practical alternative for kitchens and bathroom just where they are quickly cleaned and are reluctant to water.

Here are Images about Heated Concrete Floor Slab Specifications

Heated Concrete Floor Slab Specifications

The concrete floorings establishing has caught on and can be discovered almost everywhere today, including residential properties like high rise condominiums and also basement concerns that are restructured to develop extra room. An additional reason why lots of folks are actually choosing concrete polishing floors for their new home or maybe home renovation is actually the reduced maintenance needed.

Hydronic vs Electric u2013 Heated Polished Concrete Floors – Victoria

more and More homeowners as well as designers are developing warehouses and basements with concrete because of the look, the organic beauty, the easiness in attention and also the warmth it brings to an area. The method is simple to use with state-of-the-art technology. In case you walk into a put that has polished concrete floors, you are going to realize immediately that the dojo is fairly similar to marble.

Images Related to Heated Concrete Floor Slab Specifications

Radiant Heating :: Concrete :: Codes and Standards

Typical section details of floor heating system. Download

Radiant Heating :: Concrete :: Codes and Standards

Contraction Joints for Radiant-Heated Floors For Construction Pros

How to install a Wood or Tile Floor over Radiant Heated Floors or

The Slab on Grade Installation DIY Radiant Floor Heating

New slab with radiant heat – GreenBuildingAdvisor

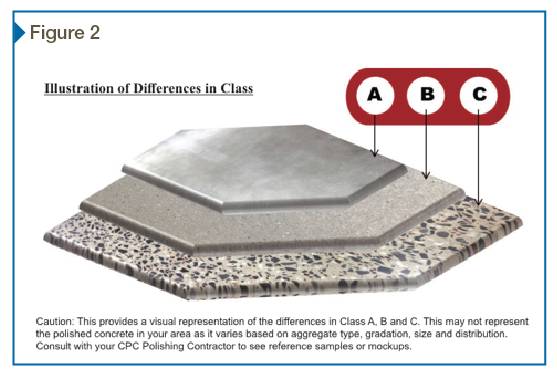

Specifying floor finishes: Polished concrete topping slabs with

How to install a Wood or Tile Floor over Radiant Heated Floors or

In floor Heating Insulation-Under Floor Heating Insulation-Radiant

Radiant Heating :: Concrete :: Codes and Standards

Radiant Heating Systems – Floors EGEE 102: Energy Conservation

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Heated Concrete Floor Slab Specifications

When it comes to heated concrete floor slab specifications, there are many variables that must be taken into account to ensure the best results. Heated concrete floor slabs are becoming increasingly popular due to their energy efficiency and ability to provide comfortable, warm floors in colder climates. This article will cover the various aspects of heated concrete floor slab specifications, as well as some frequently asked questions about this type of flooring.

Types of Heated Concrete Floors

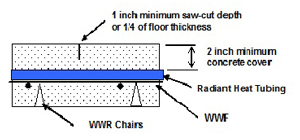

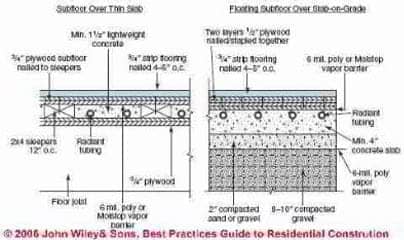

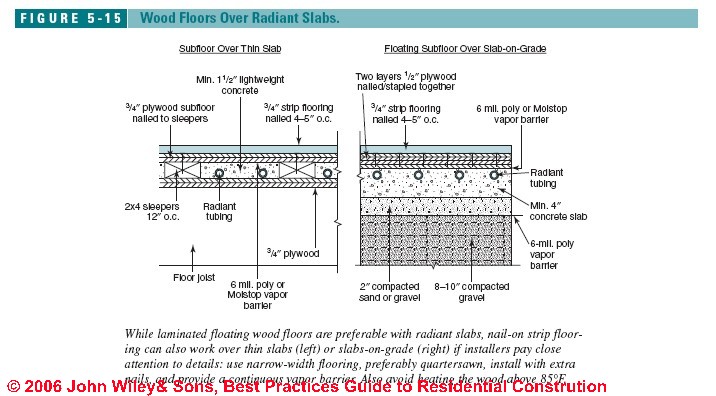

The most common type of heated concrete floor is electric radiant heat, which is relatively easy to install and maintain. Electric radiant systems can be installed in new or existing floors, and use electricity to heat up a network of wires embedded in the concrete slab. This type of system can provide a uniform heat distribution throughout the entire floor area. However, electric radiant systems tend to be more expensive than other types of heating systems, such as hydronic or boiler-based systems.

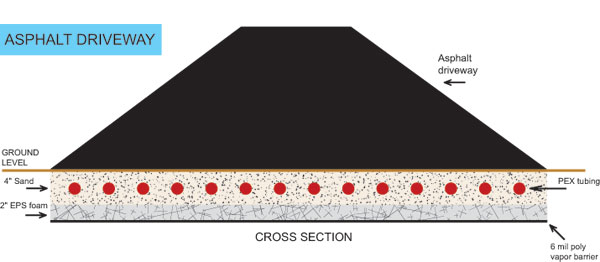

Hydronic systems use hot water pipes that run through the concrete slab, and are heated by a boiler or hot water tank. These types of systems tend to be more efficient than electric radiant systems, since they don’t require electricity for operation. However, hydronic systems also require more complex installation and maintenance procedures than electric radiant systems. Boiler-based systems are similar to hydronic systems, but they use steam rather than hot water for heating. Boiler-based systems are usually more efficient than other types of heating systems, but they also require more complex installation and maintenance procedures.

In addition to these three main types of heated concrete floors, there are also hybrid systems that combine elements from multiple heating sources for increased efficiency and customization options. Hybrid systems can be tailored to meet specific needs and preferences, such as adding zone controls for different areas of the house or utilizing different energy sources for certain times of day or seasons.

Insulation Requirements

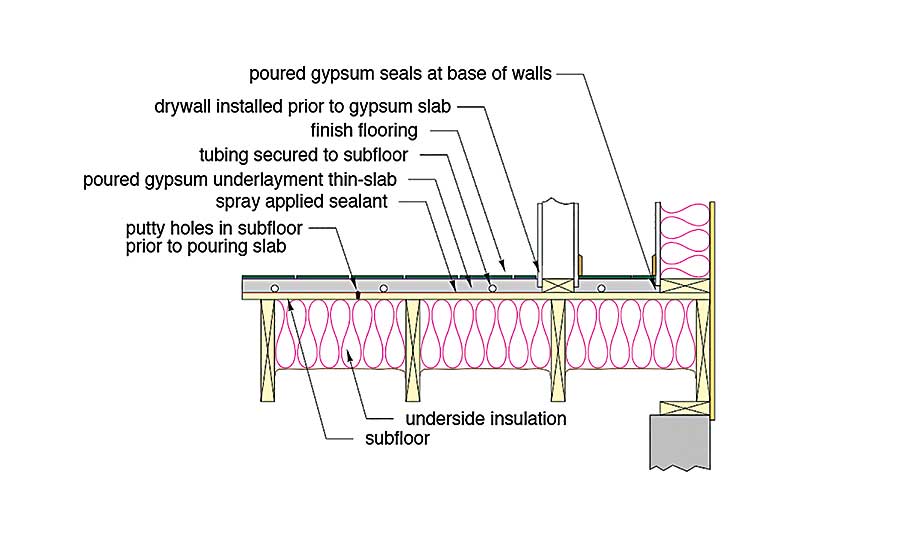

In order for a heated concrete floor system to function properly, it must be installed over an insulated subfloor. Insulation helps keep warm air from escaping out the bottom of the slab, which improves efficiency and reduces energy costs. The insulation should also be thick enough so that it does not compress over time due to foot traffic or furniture placement on top of it. Generally speaking, a minimum R-value (a measure of thermal resistance) of at least R-10 is recommended for most residential applications with heated concrete floors. For commercial applications with higher foot traffic or heavier furniture placement on top of the system, an even higher R-value may be needed in order to prevent compaction over time.

Thermostat Controls

Thermostat controls are essential for any type of heated concrete floor system in order to ensure proper temperature settings and energy efficiency. Most thermostats come with pre-programmed settings designed specifically for different types of heating systems, such as electric radiant or hydronic systems. Depending on the system being used, thermostats may also be able to control multiple zones within a single building in order to customize heating levels for each area accordingly. In addition to providing energy efficiency benefits, thermostats can also help prevent overheating by automatically turning off the heat when it reaches a certain temperature level.