The advantages of having the wood floor of yours oiled would be that it is going to keep for longer and will additionally slow down aging so you can preserve the colour you initially bought. Engineered wood flooring is built to be stable, and solid wood flooring could simply not compete in this particular arena. Another advantage is that the factory finishes are generally much tougher than the polyurethane applied in the field.

Images Related to What Is Engineered Wood Flooring Made Of

What Is Engineered Wood Flooring Made Of

/cdn.vox-cdn.com/uploads/chorus_asset/file/19489671/02_about_wood_floors_x.jpg)

Selecting the best real wood flooring is crucial if you want to get the best durability and longevity for your money. These benefits encourage numerous home owners to make use of laminate wood flooring while remodeling their houses. Nowadays, wood flooring is now being done in unique and custom designs as borders, medallions, hand-distressing, painting, mixed media, stain and exotic wood.

What is Engineered Wood Flooring? Engineered Hardwood

Wood floors are the healthy option, they require far fewer chemical compounds to clean than many other floor coverings, & they do not catch dust and also fumes in the fibers or perhaps develop mold of the grout. Generally take existing flooring so you're to floorboards/ concrete, then lay foam underlay by which timber goes onto. When old buildings, industrial buildings, barns, bridges, and other types of nuts.

ENGINEERED WOOD FLOOR An Architect Explains And Reviews

How is Engineered Flooring Made Woodpecker Flooring

Engineered Hardwood u2013 Honest Home

Difference Between Solid and Engineered Hardwood Floors

Solid Wood vs. Engineered Wood Flooring Comparison Guide

Whatu0027s Better: Solid vs Engineered Hardwood Flooring – LV Hardwood

Hardwood Vs. Engineered Wood Flooring u2013 Which Is Best For You

Solid vs. Engineered – Quality Hardwoods, Superior Design Palo

What is engineered wood flooring?

What is Engineered Wood ? 7 Facts You Never Knew About It

The Evolution of Engineered Hardwood Flooring BuildDirect

All About Engineered Wood Flooring

Related articles:

- Natural Wood Floor Stain

- Oak Wood Flooring

- Birch Wood Flooring Reviews

- Wood Floor Damage Repair

- Dove Grey Wood Flooring

- Engineered Wood Floor Bathroom

- What Is Composite Wood Flooring

- Wood Floor Covering Options

- Black Solid Wood Flooring

- Best Wood Floor Filler

What Is Engineered Wood Flooring Made Of

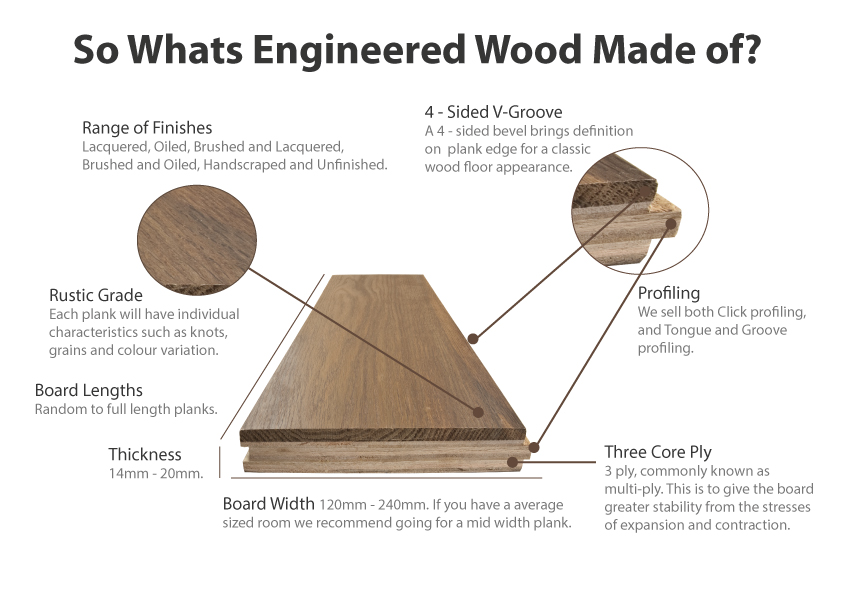

Engineered wood flooring is a popular choice among homeowners and designers due to its durability, versatility, and aesthetic appeal. As the name suggests, this type of flooring is made from engineered wood, which is a composite material consisting of multiple layers of wood veneer. In this article, we will take a closer look at what engineered wood flooring is made of and explore its various components in detail.

1. The Top Layer: Hardwood Veneer

The top layer of engineered wood flooring is composed of hardwood veneer. This layer can vary in thickness, typically ranging from 2mm to 6mm, depending on the specific product. Hardwood veneer brings the natural beauty and warmth of real wood to the flooring, creating an authentic and luxurious appearance.

FAQ: How does the thickness of the hardwood veneer affect the durability of engineered wood flooring?

The thickness of the hardwood veneer directly impacts the longevity and durability of engineered wood flooring. A thicker veneer provides more wear resistance and allows for multiple refinishing processes throughout the floor’s lifespan. Thicker veneers also offer better protection against scratches, dents, and other forms of damage.

2. The Core Layer: Plywood or High-Density Fiberboard (HDF)

Beneath the hardwood veneer lies the core layer of engineered wood flooring. This layer is typically made from plywood or high-density fiberboard (HDF). Plywood is constructed by gluing together multiple layers of thin wood sheets, with each layer’s grain direction perpendicular to the adjacent one. HDF, on the other hand, is made by compressing wood fibers under high pressure and heat.

FAQ: What are the advantages of using plywood as the core layer in engineered wood flooring?

Plywood offers several advantages as a core material for engineered wood flooring. Firstly, it provides dimensional stability, allowing the floor to withstand changes in temperature and humidity without warping or cupping. Secondly, plywood has good structural strength, ensuring the durability and longevity of the flooring. Lastly, plywood is a sustainable choice as it can be made from fast-growing tree species, minimizing environmental impact.

FAQ: What are the benefits of using HDF as the core layer in engineered wood flooring?

HDF is a popular choice for the core layer in engineered wood flooring due to its high density and uniform composition. It offers excellent moisture resistance, making it suitable for installation in areas prone to moisture, such as basements and bathrooms. Additionally, HDF provides a smooth and stable surface for the hardwood veneer, enhancing the overall performance and aesthetics of the flooring.

3. The Bottom Layer: Backing Material

The bottom layer of engineered wood flooring serves as a backing material and plays a crucial role in providing stability and moisture resistance. It is typically made from thin layers of wood or a synthetic material such as melamine.

FAQ: Why is moisture resistance important in the backing material of engineered wood flooring?

Moisture resistance is vital in the backing material of engineered wood flooring to prevent water damage and warping. Moisture can seep through the subfloor and reach the backside of the flooring if not adequately protected. By using a moisture-resistant backing material, such as melamine or certain types of wood, the flooring remains stable and durable even in humid environments.

4. Adhesive: Binding It All Together

To ensure that all the layers of engineered wood flooring stay securely bonded, an adhesive is used during manufacturing. This adhesive is Applied between each layer to create a strong and stable flooring product. The type of adhesive used can vary, but it is typically a water-resistant or waterproof adhesive to further enhance the moisture resistance of the flooring. The adhesive also helps to prevent delamination, where the layers of the flooring separate over time. It is important to use a high-quality adhesive to ensure the longevity and durability of the engineered wood flooring. Using plywood as the core layer in engineered wood flooring has several advantages. Firstly, plywood provides dimensional stability, meaning it can withstand changes in temperature and humidity without warping or cupping. This is important for maintaining the overall appearance and structural integrity of the flooring. Additionally, plywood has good structural strength, ensuring the durability and longevity of the flooring. Lastly, plywood is a sustainable choice as it can be made from fast-growing tree species, minimizing environmental impact.

On the other hand, HDF (High-Density Fiberboard) is a popular choice for the core layer in engineered wood flooring due to its high density and uniform composition. HDF offers excellent moisture resistance, making it suitable for installation in areas prone to moisture, such as basements and bathrooms. It also provides a smooth and stable surface for the hardwood veneer, enhancing the overall performance and aesthetics of the flooring.

The bottom layer of engineered wood flooring serves as a backing material and plays a crucial role in providing stability and moisture resistance. It is typically made from thin layers of wood or a synthetic material such as melamine. Moisture resistance is important in the backing material to prevent water damage and warping. By using a moisture-resistant backing material, such as melamine or certain types of wood, the flooring remains stable and durable even in humid environments.

To ensure that all the layers of engineered wood flooring stay securely bonded, an adhesive is used during manufacturing. This adhesive is applied between each layer to create a strong and stable flooring product. The type of adhesive used can vary but is typically a water-resistant or waterproof adhesive to further enhance the moisture resistance of the flooring. The adhesive also helps to prevent delamination, where the layers of the flooring separate over time. Using a high-quality adhesive is important to ensure the longevity and durability of the engineered wood flooring. The adhesive used in engineered wood flooring is applied between each layer to ensure a strong and stable bond. It is typically a water-resistant or waterproof adhesive, which helps enhance the moisture resistance of the flooring. The adhesive also prevents delamination, where the layers of the flooring separate over time. Using a high-quality adhesive is crucial for the longevity and durability of the engineered wood flooring.